Hauptinhalt

Geräte

Charakterisierung

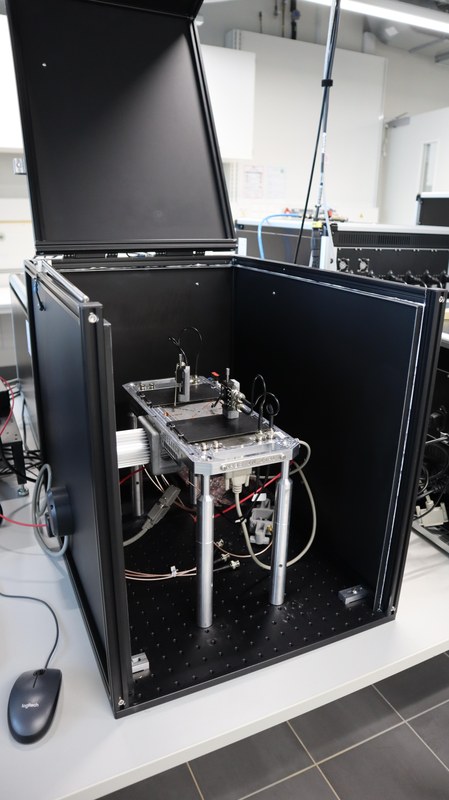

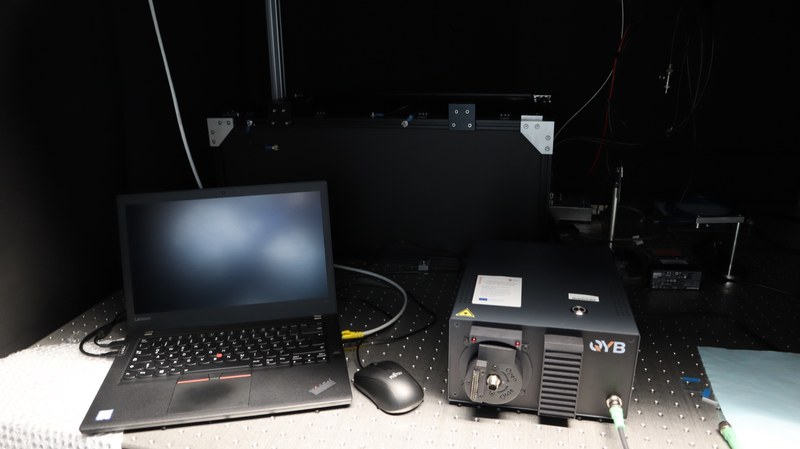

Inhalt ausklappen Inhalt einklappen EQE

AG Goldschmidt intern The EQE Setup (also IPCE) is able to perform multiple measurements such as Dark JV, IPCE, EL-PL-Spectrum, Pulsed EL, 4-Point Probe (all steady state) or Transient Photo Response, Electrical Impendance Spectroscopy and Charge Extraction by Linearly Increasing Voltage (all transient).

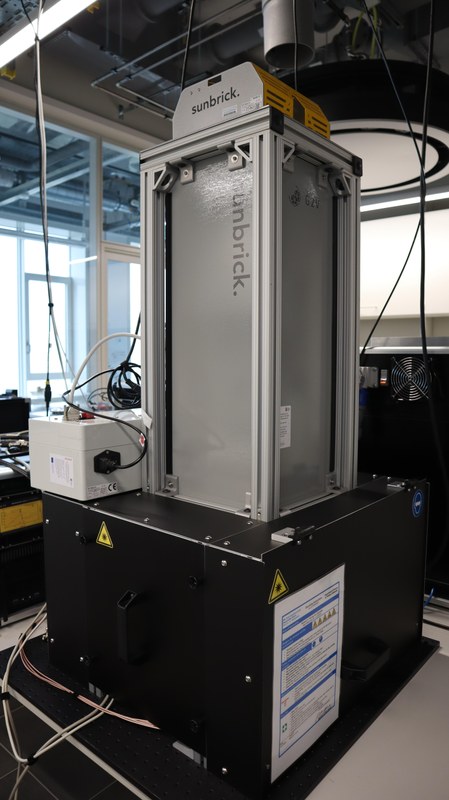

Inhalt ausklappen Inhalt einklappen Sun Simulator IV

AG Goldschmidt intern The exceeding Class A Sun Simulator offers a high precision spectral mismatch of < 5%. Typical measurements performed are JV scans and maximum powerpoint tracking.

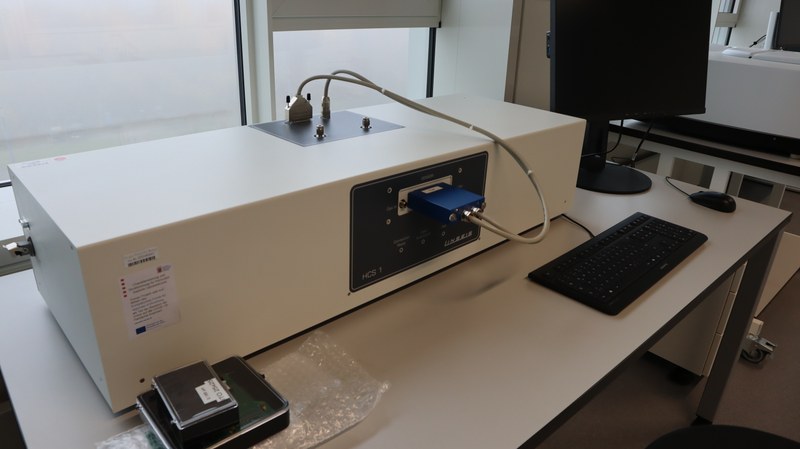

Inhalt ausklappen Inhalt einklappen Hall Setup

AG Goldschmidt intern The Hall Setup does measurements of resistance of thin film using the Van der Pauw method. It allows the caracterization of semiconductor devices regarding their electric transport properties, like the Hall mobility, Charge Carrier Concentration, Resistivity and the Seebeck Coefficient.

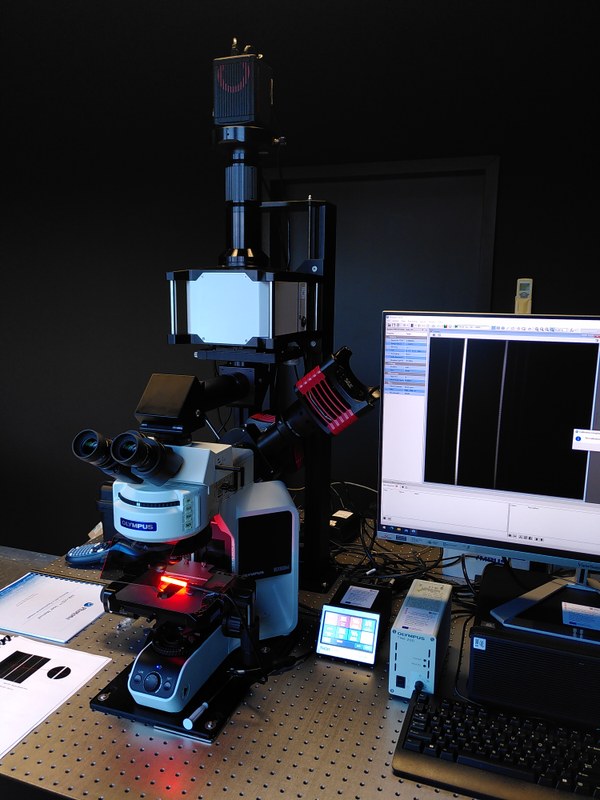

Inhalt ausklappen Inhalt einklappen Hyperspectral Imaging

Foto: Jan Christoph Goldschmidt This Hyperspectral Imager can be used to collect a full spectrum of every pixel and to map Bandgap variations, Material composition differences, Phase segregation, Crystallinity variations and defects. Also PL and EL mappings can be done for example to determine the QFLS.

Inhalt ausklappen Inhalt einklappen Photoluminescence quantum yield (PLQY)

AG Goldschmidt intern This system can be used to quantify absolute electro- and photoluminescence fluxes of thin film absorbers, layer stacks or complete devices under various operating conditions.

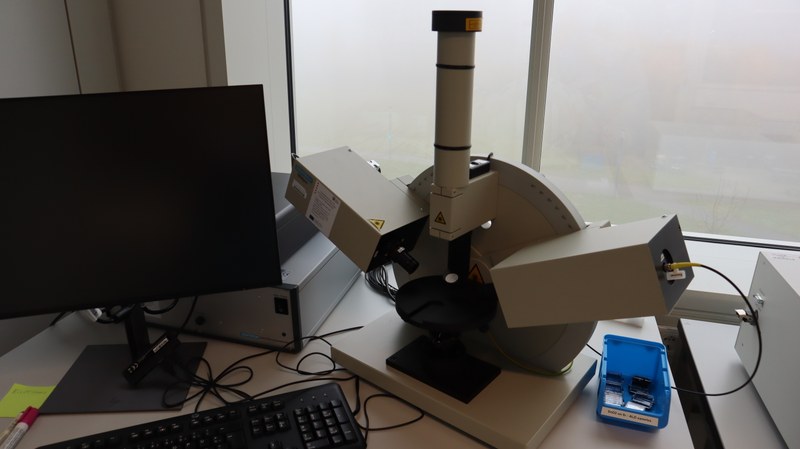

Inhalt ausklappen Inhalt einklappen Ellipsometer

AG Goldschmidt intern An ellipsometer is used to precisely measure thin-film optical and physical properties. It works by shining polarized light onto a surface and analyzing how the polarization changes after reflection. Therefore it can be used to map the uniformity across the sample, characterize surface roughness or to identify material compositions and bandgap shifts.

Inhalt ausklappen Inhalt einklappen Time Resolved Photoluminescence

AG Goldschmidt intern This technology can be used to understand the behaviour of charges over time after photoexcitation. The TRPL measures how fast a material emits light, which gives direct insight into recombination dynamics.

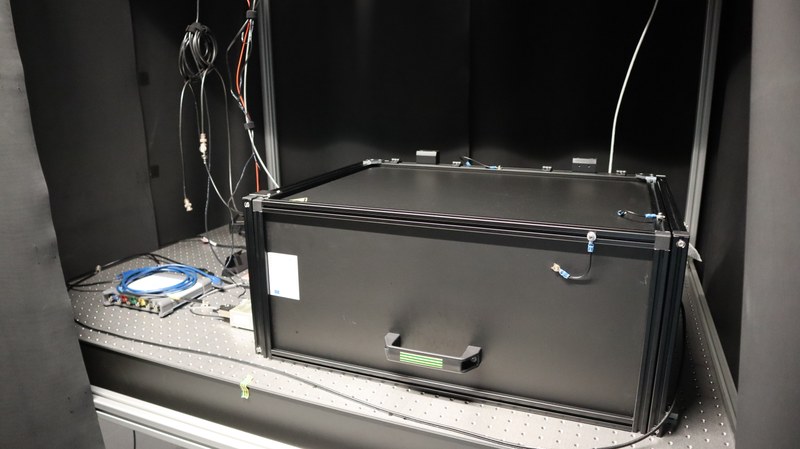

Inhalt ausklappen Inhalt einklappen Ageing Setups

AG Goldschmidt intern

AG Goldschmidt intern Our light soaking chambers consist of multiple arrays of LED’s to achieve a high level of homogeneity. In addition we are using a self-built temperature station to have full control over the temperatur during the measurements and different sensors to check the humidity, O2 levels and the luminous intensity.

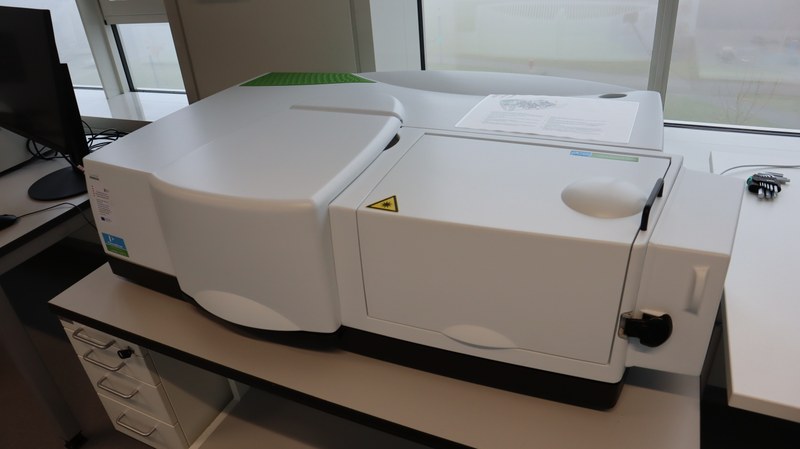

Inhalt ausklappen Inhalt einklappen UV-Vis

AG Goldschmidt intern The UV-Vis can measure the reflection and transmission of a material and provides us with information about the absorption behaviour. It also allows us to extract the bandgap from the semiconductors.