Main Content

Devices

Production

Glovebox for wet-chemical deposition and spin-coating

AG Goldschmidt intern These Gloveboxes are used during the production of our perovskite solar cells. Among other things, the spin coating process takes place there.

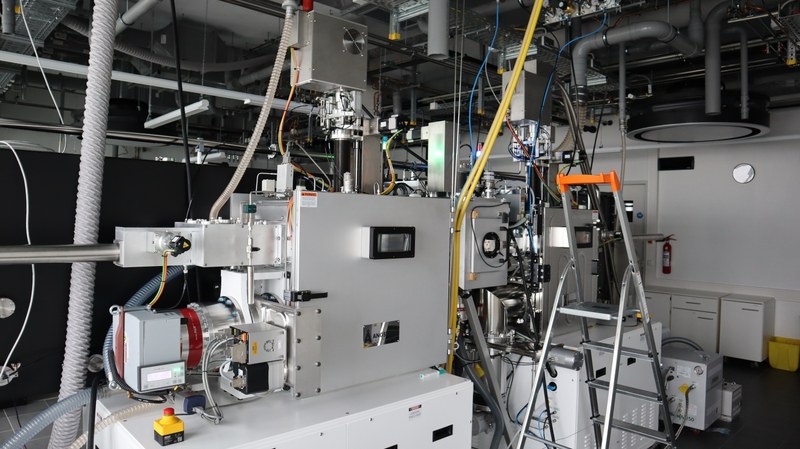

Evaporation System

AG Goldschmidt intern

AG Goldschmidt intern Our new glovebox-integrated thin-film deposition cluster enables high-precision fabrication of perovskite solar cells under fully controlled inert conditions. The system combines thermal evaporation and sputtering chambers with an automated multi-level load-lock, allowing sample transfer without breaking vacuum. Direct integration with our X-ante transfer chamber and ALD systems supports advanced multilayer device architectures and fully reproducible research workflows.

Atomic Layer Deposition

AG Goldschmidt intern Atomic layer deposition (ALD) is a thin-film technique that uses sequential, self-limiting surface reactions to deposit materials with sub-nanometer thickness control and excellent conformality. It is commonly used to create high-quality passivation layers buffer layers, and barrier coatings that improve device efficiency and stability.

Fume Hood and Heat Press

AG Goldschmidt intern The heat press is mostly used for carbon electrodes to apply controlled temperature and pressure. It helps to achieve a dense and well-contacted carbon layer, that improves the conductivity.

Wet-chemical Fume Hood for Substrate Cleaning

AG Goldschmidt intern A wet-chemical fume hood for substrate cleaning allows the performance of processes like acid/base cleaning, etching and rinsing substrates.

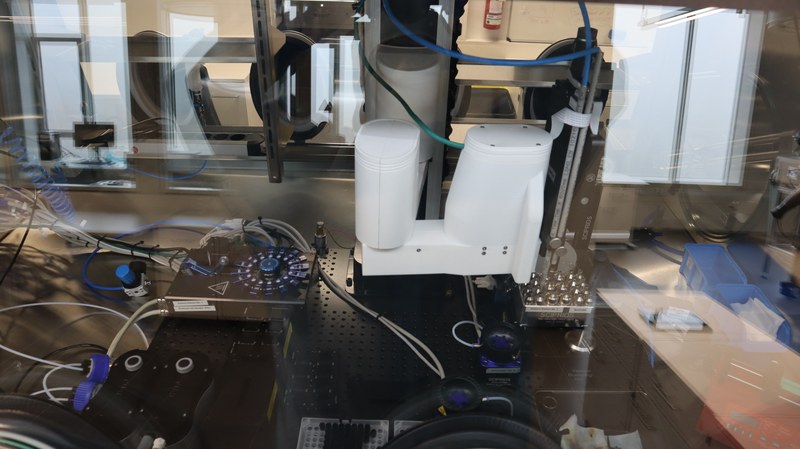

Spincoating Robot

AG Goldschmidt intern This automated system deposits thin, uniform films on substrates by dispensing a solution and spinning it at controlled speeds. With the help of the spinbot, our solar cells reach a high reproducibility and uniform thickness.