Main Content

Characterization of All-Solid-State Batteries

Summary:

All-solid-state batteries (ASSBs) hold great promise for becoming the next-generation energy source of electric vehicles. As compared to state-of-the-art lithium-ion batteries containing flammable liquid electrolytes, ASSBs offer potentially higher energies densities due to the usage of Li metal as anode material and higher safety due to the non-flammability of many solid electrolytes.

Major challenges in the field of ASSBs are, however: (i) Design of composite electrodes with stable contacts between active material particles and solid electrolyte particles (ii) Development of cheap and scalable production methods for ASSBs.

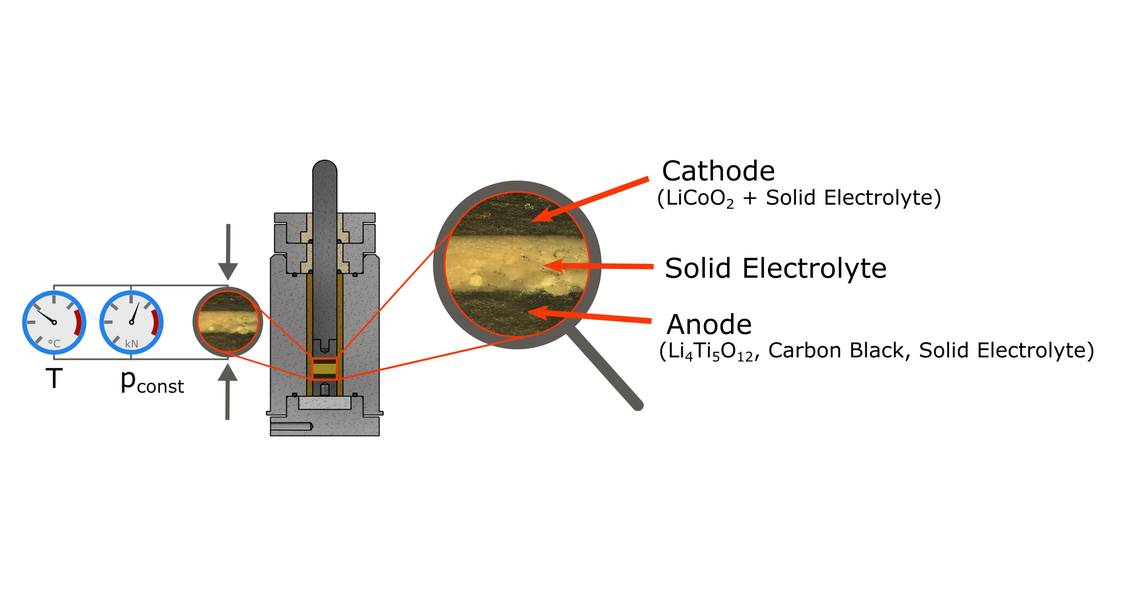

Novel measuring system for all-solid-state battery characterization under well-defined pressure and temperature

In order to study the influence of pressure and temperature on the particle contacts in composite electrodes, we use a novel measuring system, in which lab-scale all-solid-state battery cells can be cycled and characterized under well-defined pressure and temperature conditions.

Figure 1: Measuring system for all-solid-state batteries COMPRE DRIVE (rhd instruments).

Coating of active material particles with soluble solid electrolytes

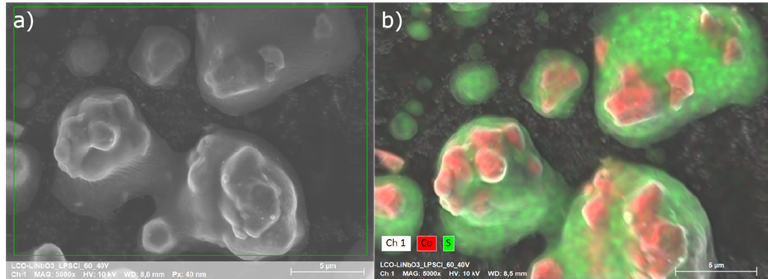

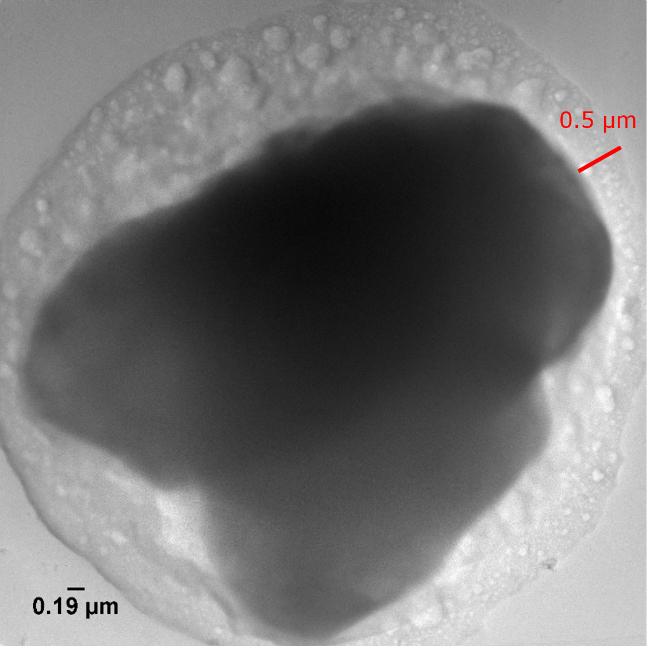

In order to achieve fast ion transport pathways in all solid-state battery electrodes, active material particles can be coated with solid electrolytes by means of solution chemistry (Figure 2 and 3). For this purpose, amorphous electrolytes are advantageous, since low annealing temperatures are sufficient for achieving an amorphous electrolyte layer on top of the active material particles. The coating procedure has to be optimized to ensure a homogeneous distribution of active material particles and solid electrolyte particles inside the composite electrode.

Figure 2: Li6PS5Cl- coated LiCoO2 particles with a volume ratio of 60 vol% LiCoO2 and 40 vol% Li6PS5Cl. a) SEM image, b) EDX image with red: cobalt and green: sulfur.

Figure 3: TEM image of a Li6PS5Cl- coated LiCoO2 particle. Dark: LiCoO2 particle. Bright: Li6PS5Cl coating.

Sheet-type all-solid-state-batteries

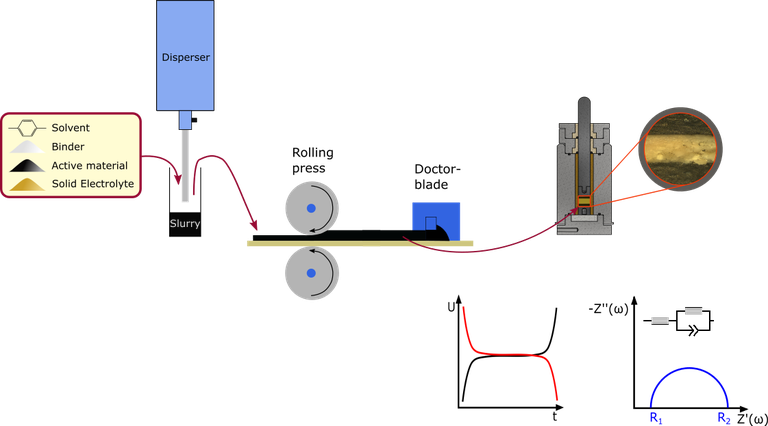

Commercial liquid batteries are widely fabricated by slurry-based coating processes. ASSBs in the laboratory, on the other hand, are predominantly assembled by pressing the individual components (cathode-electrolyte composite | electrolyte | anode) under high pressures. However, this process cannot be implemented for large scale production of ASSBs. Therefore, it is desirable to apply the well-known and easily scalable slurry-coating approach to ASSBs. In this case, a slurry, consisting of a polymeric binder dissolved in a non-reactive solvent and subsequently mixed with the active material and solid electrolyte particles, is casted on top of a substrate. Afterwards, it can readily be punched into the shape of choice.

We study various electrolyte systems in combination with common cathode and anode materials in order to build and electrochemically characterize these promising sheet-type ASSBs. Furthermore, we compare the performance with ordinary cold-pressed ASSB cells in order to elucidate the influence of the polymeric binder on the battery performance. Ultimately, we aim at deducing design and assembling strategies for the further development towards commercial ASSB cells.

Figure 4: Fabrication of Sheet-type All-Solid-State-Batteries.