Hierarchically Porous Monoliths

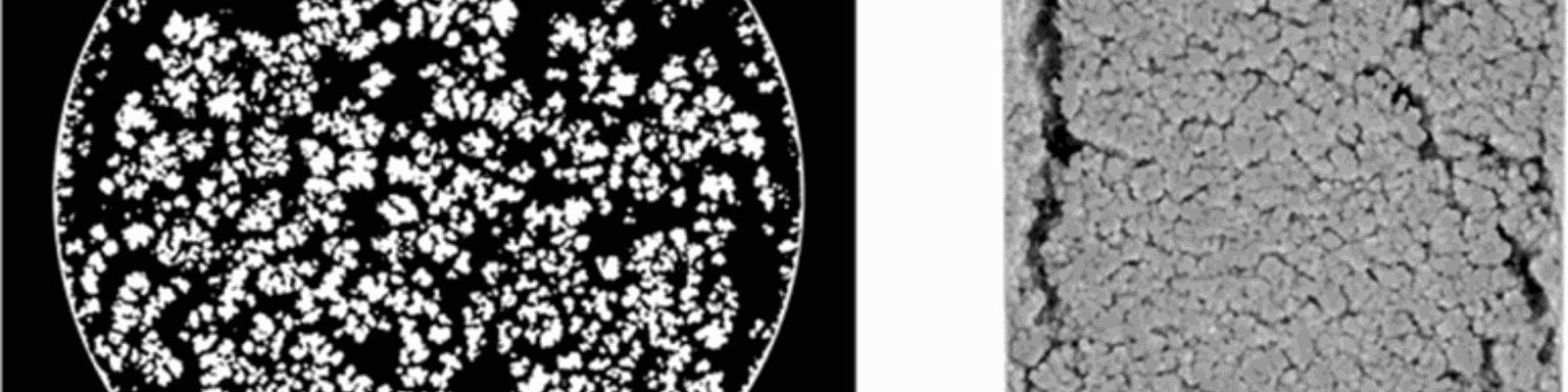

Macroporous‒mesoporous materials inside a containing geometry come in two different architectures: packed beds of discrete mesoporous particles, where the larger, flow-through pores are formed by the space between the macrosized particles, or continuous beds (monoliths) with interstitial macropores and a mesoporous skeleton. The most important flow characteristics of fixed beds, hydraulic permeability and the residence time distribution of solute molecules, are determined by the bed morphology, specifically the bed porosity (void volume fraction) and size of the flow-through pores. From the local pore scale up to the bulk material scale, monoliths offer more design variability than conventional particulate beds, allowing a unique combination of selectivity, mobile phase velocity, heat and mass transfer, and specific surface area. For example, mechanically stable particulate packings can only be obtained at bed porosities between (roughly) 0.36 and 0.46, so that the size of their interparticle flow-through pores is inherently linked to the particle size. The interstitial porosity of monoliths (their macroporosity) typically ranges from 0.5 to 0.75 (with smaller and larger values possible), and the macropore size can be varied independently from the skeleton thickness. This allows a fine-tuning of the external surface area, which is especially important for applications involving large biomolecules, where the external surface area determines the adsorbent capacity.

The solid phase of particulate or monolithic fixed beds can be a hard or soft matter material. The first category comprises mainly metal and nonmetal oxides, most prominently silica, the second category organic polymers. Porous silica is mechanically stable at high pressures and can be synthesized into particles with diameters ranging from submicron to sub-mm size as well as into monolithic structures. On the downside, silica-based materials tolerate a small pH-range, are incompatible with a number of solvents, and their surface modification is limited, difficult, and always leaves residual surface silanol groups that can interact with solute molecules in an undesirable fashion. Polymer-based materials have reduced mechanical stability, but are more resilient against aggressive chemicals and leave a chemically inert backbone after modification. Their most important asset, however, is the wide range of possible and straightforward surface modifications. Our goal in this research area is to identify the structural limitations of monoliths regarding their efficiency in flow-driven applications to provide a morphology-based foundation for directed synthetic efforts.